- 01535 652338

- mail@watsonsbs.com

Path To Net Zero: Everything You Need to Know About R32 Refrigerant Systems

R32 is a lower Global Warming Potential (GWP) refrigerant increasingly used in modern Variable Refrigerant Flow (VRF) systems to reduce carbon emissions and improve overall system efficiency. Because refrigerant is the medium that transfers heat within an HVAC system, its environmental impact plays a critical role in determining a building’s overall sustainability. Adopting refrigerants like R32 is therefore a key step in supporting the transition to Net Zero buildings.

As part of our Path to Net Zero series, we’re exploring how Heat Recovery VRF systems, alongside advancements in refrigerants, are helping create more energy-efficient, cost-effective, and environmentally responsible buildings.

How VRF Systems Work

VRF systems use refrigerant as their primary heating and cooling medium, transferring heat by circulating it between indoor and outdoor units. A typical system consists of:

- Multiple indoor air handling units

- An outdoor inverter-driven compressor

- Low- and high-pressure refrigerant pipework

Each indoor unit continuously monitors room temperature and occupancy. When the desired temperature is reached, or when a space is unoccupied, the system reduces or shuts off refrigerant flow to that area. This precise control ensures energy is only used where and when it is needed, significantly increasing efficiency.

Why Refrigerant Choice Matters

Mechanical and digital control advances have made contemporary VRF systems highly efficient. However, true sustainability depends on the combined performance of every component, including the refrigerant.

Since refrigerant carries heat throughout the system, it represents a substantial portion of the system’s environmental impact. Lower-GWP options such as R32 enable VRF systems to deliver the same high performance while significantly reducing greenhouse gas emissions.

In short, improving HVAC sustainability isn’t just about smarter systems — it’s also about using greener refrigerants.

The Evolution Of Sustainable Refrigerants

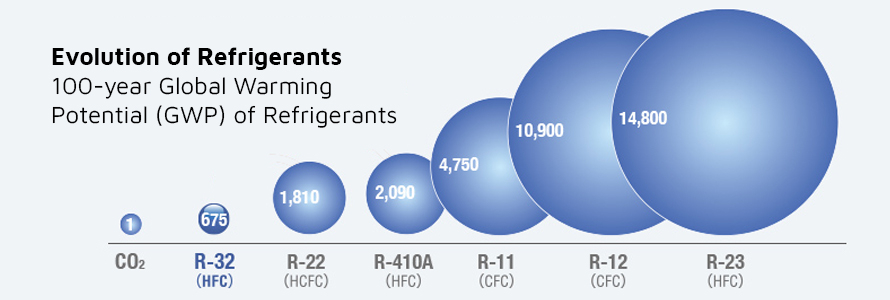

Over the years, there have been many types of refrigerants. Unfortunately, they have had negative environmental impacts, to the point where they have been banned from use. Early refrigerants in the VRF process were made from chlorofluorocarbons, the now-infamous CFC gas. These were phased out in the late 1980s and replaced by hydrochlorofluorocarbons (HCFCs), from which a common and recognised refrigerant called Freon (R12) was widely manufactured and put into use. Although it made for some reduction in global warming potential (GWP - the unit developed as a metric to compare, relative to Carbon Dioxide, the ability of each greenhouse gas to trap heat in the atmosphere), it did not go very far.

Refrigerants R410A and R22 were initially put into mainstream use as they featured either a zero, or very low Ozone Depletion Potential (ODP) rating, but their GWP remained unacceptably high, to the point where they too are now in the process of being phased out. With an EU ban on the use of these refrigerants by 2025 looming, the race to develop a solution was on.

Image source: www.daikin.com

Necessity being the mother of invention, the end result has been an elegant solution called R32. With a GWP below the prohibited 750 watermark, a high level of energy efficiency, and lower costs to produce, R32 has now become the prominent refrigerant for HVAC use - and the only non-prohibited option in Europe as of January 2025. The previous refrigerants have been the subject of a phase-out plan over the last few years, culminating in the full ban. For building managers and developers in the UK, the adoption of this legislation following EU withdrawal means choices will have to be made when readying themselves for the switch.

How R32 Compares To Previous Refrigerants

- Global Warming Potential (GWP): R32 has a lower GWP (657) compared to R22 (1810) and R410A (2088). The lower GWP of R32 means it has a lower impact on the environment compared to R22 and R410A

- Energy efficiency: R32 has a higher energy efficiency compared to R22 and R410A, which means that air conditioning systems using R32 require less energy to operate and can result in lower electricity consumption and cost

- Flammability: R32 has a lower flammability compared to R22 and R410A, making it a safer option for air conditioning systems

- Toxicity: R32 is considered to be less toxic compared to R22 and R410A, but it should still be handled with caution to avoid potential harm to humans and the environment

- Pressure: R32 operates at a lower pressure compared to R22 and R410A, which can result in smaller and lighter components for air conditioning systems

- Cost: R32 is generally less expensive compared to R22 and R410A, making it a more cost-effective option for air conditioning systems

| Refrigerant | R32 | R22 | R410A |

| Global Warming Potential (GWP) | 657 | 1810 | 2088 |

| Energy Efficiency | High | Low | Moderate |

| Flammability | Low | Moderate | Moderate |

| Toxicity | Low | Moderate | Moderate |

| Pressure | Low | High | High |

| Cost | Low | High | Moderate |

Making The Change To R32

Fortunately, there is good news for managers and developers. The R32 refrigerant can be backwards compatible, meaning that it may be possible to retrofit existing R410a systems so that they can use R32.

It is not a simple plug-and-play process, however. Upgrading an existing system means significant modifications and careful handling due to the different chemical properties and pressures of R32 compared to older refrigerants like R410A. The process requires skilled HVAC technicians, trained in R32 handling and specific knowledge of VRF systems.

Our Process for Upgrading to R32

01 Initial Inspection

- Assessment: Our HVAC specialists conduct a thorough inspection of the existing VRF system to determine its compatibility with R32.

- Component Evaluation: Key components such as compressors, heat exchangers, and piping are evaluated to ensure they can handle the different properties of R32.

02 Component Replacement

- Compressor: In some cases, the existing compressor may need to be replaced with one compatible with R32.

- Heat Exchangers: These may also need to be upgraded to handle the higher pressures associated with R32.

- Piping and Valves: The existing piping and valves might need to be replaced or modified to accommodate the different flow characteristics of R32.

03 System Cleaning

- Flushing: The system must be thoroughly flushed to remove any residual R410A refrigerant and oil, as mixing refrigerants can lead to inefficiencies and potential damage.

04 Refrigerant Charging

- R32 Charging: The system is then charged with R32 refrigerant. This process requires precise measurement and handling due to the flammability of R32.

05 System Testing

- Leak Testing: The upgraded system is tested for leaks to ensure safety and efficiency.

- Performance Testing: The system’s performance is evaluated to ensure it meets the desired heating and cooling capacities.

The initial cost of upgrading can be high due to the need for new components and professional engineers, the long-term benefits include improved energy efficiency, which can significantly lower the energy costs. Along with the positive environmental impact, upgrading to R32 ensures compliance with current and future environmental regulatory frameworks, such as the EU’s F-Gas regulations.

Our HVAC technicians are fully trained and experienced in upgrading VRF systems to R32. Find out more about our HVAC solutions and contact us to begin your upgrading process.