- 01535 652338

- mail@watsonsbs.com

Path To Net Zero: How VRF and Heat Recovery is Changing The Game

In the built environment, sustainability significantly influences the value and running costs of properties. Sustainable buildings must offer comfort, health, and safety to occupants while minimising waste and environmental impact. However, outdated mechanical systems and fuel sources can impede a building’s ability to transition to sustainability.

While some technologies are still evolving towards more environmentally friendly alternatives, the Heating, Ventilation and Air Conditioning (HVAC) sector has had energy-efficient, sustainable solutions available for many years. Development of these systems continues apace as the industry advances towards the goal of net zero.

First introduced in the early 80s, Variable Refrigerant Flow (VRF) introduced the ability to individually control the environmental conditions across multiple rooms or zones - a huge challenge up until that point for building developers. Following the incorporation of heat recovery technology into the system, VRF became the game changer for achieving sustainability in commercial buildings, ushering in a new era of energy efficiency.

How Does A Variable Refrigerant Flow System Work?

Variable Refrigerant Flow is another name for Variable Refrigerant Volume (VRV), the system originally invented in 1982 by Japanese HVAC pioneers Daikin Industries. VRV was trademarked by Daikin, which is why copycat systems are referred to as VRF. However, the technology is the same.

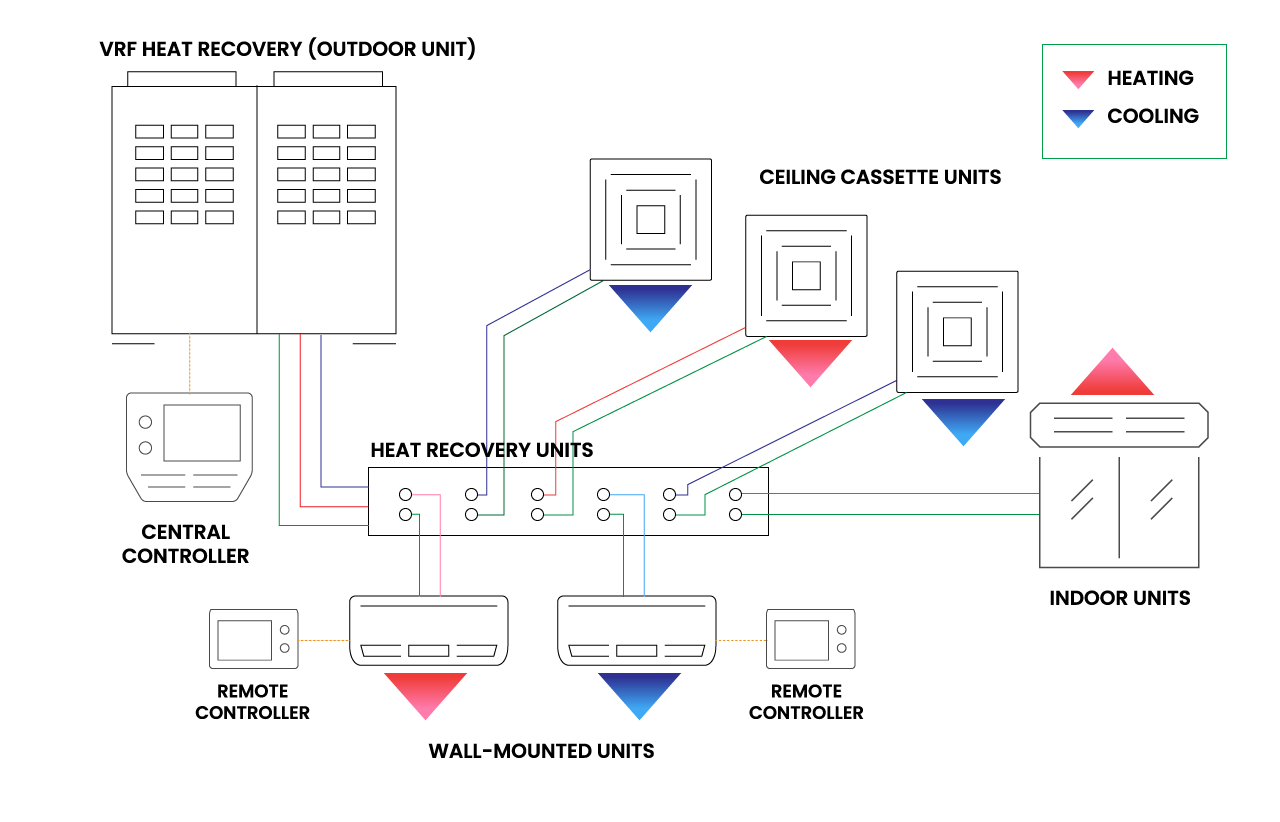

VRF systems typically consist of multiple indoor air handling units, an outdoor inverter compressor, and low-temperature and high-temperature gas and pressure lines. VRF uses refrigerant as its primary heating and cooling medium, alternating the refrigerant volume in a system to match a building's precise requirements.

The system divides a building into zones with individual set points based on usage, occupancy, and user preferences. Only a minimum amount of energy is required to maintain set temperatures and ensure that it automatically shuts off when no occupants are detected in a room.

How does Heat Recovery VRF work?

There are three main types of VRF systems in use - cooling only, heat pump, and heat recovery. Cooling only was the original design, and is obvious in what it provides. Heat Pump VRF is a two-pipe system that will use the indoor units to either heat or cool, but not both simultaneously. The Heat Recovery VRF system, however, is a three-pipe system that brings the versatility needed to make VRF systems a serious energy saver.

A VRF system engineered for heat recovery extracts heat from zones being cooled and transfers it to the zones requiring heating. The third pipe in this system extracts the waste thermal energy from one unit and transfers it to the rest of the system. This significantly decreases the energy required by the system - in some cases by more than 30%.

The benefits from this system are most keenly felt in buildings with high occupancy, where the most energy consumption per building has traditionally been found. Hotels, office blocks, hospitals, residential buildings, and indoor shopping malls are just some of the heavily occupied spaces that have various heating and cooling demands from area to area within the building. Heat Recovery VRF has become indispensable to occupant comfort, cost-effectiveness, and sustainable practice, due to its ability to simultaneously heat and cool within a single system.

Advantages Of A Heat Recovery Variable Refrigerant Flow System

Energy efficiency and sustainability have been the focal points of Heat Recovery VRF systems since their inception, but the advantages to commercial buildings, their owners, and occupants go further.

- Quiet Operation: Heat Recovery VRF systems are designed to operate quietly, making them ideal for environments where noise levels need to be minimal, such as offices, hotels, and residential buildings.

- Enhanced Comfort: By providing precise temperature control and maintaining consistent humidity levels, Heat Recovery VRF systems enhance overall indoor comfort.

- Scalability: Heat Recovery VRF systems are scalable, making them suitable for both small and large buildings. They can be easily expanded to accommodate future growth.

- Reliability: These systems are known for their durability and reliability, with fewer breakdowns and maintenance needs compared to traditional HVAC systems.

- Remote Monitoring and Control: Many Heat Recovery VRF systems come with advanced control options, including remote monitoring and control, which can improve system management and maintenance.

- Improved Air Quality: With better control over humidity and temperature, Heat Recovery VRF systems can contribute to improved indoor air quality, reducing the risk of mould and other air quality issues.

R32 Refrigerant - A More Sustainable Medium

As the medium through which the VRF system conveys heat, refrigerant constitutes a significant share of the VRF process. The ability for a system to reduce its carbon footprint is only possible through the sum of its parts, so developing a greener medium is vital.

Within the last few years, the evolution of refrigerants has led to the development of R32, which will soon become the only gas allowed within HVAC systems. R32 is an incredibly elegant solution to the issue of greenhouse gas emissions, featuring the following benefits to sustainable building energy management:

- Global Warming Potential (GWP): R32 has a GWP of 657, which means it has a lower impact on the environment compared to previous refrigerants, and falls within regulatory tolerances.

- Energy efficiency: R32 has a highly rated energy efficiency, which means that air conditioning systems using R32 require less energy to operate and can result in lower electricity consumption and cost.

- Flammability: R32 has a low flammability, making it a safer option for air conditioning systems.

- Toxicity: R32 is considered to be less toxic, but it should still be handled with caution to avoid potential harm to humans and the environment.

- Pressure: R32 operates at a low pressure which can result in smaller and lighter components for air conditioning systems.

- Cost: R32 is generally less expensive, making it a more cost-effective option for air conditioning systems.

For a deeper look at R32 and how Watsons can help bring your existing system up to regulation, take a look at our companion article Path To Net Zero: Everything You Need to Know About R32 Refrigerant Systems.

Left: Changing the filter on an inside air unit. Right: A Heat Recovery Unit

Upgrading To A Heat Recovery Variable Refrigerant Flow System

Heat Recovery Variable Refrigerant Flow technology provides a cleaner and more efficient method for heating and cooling buildings. As an all-electric system, Heat Recovery VRF eliminates the need for fossil fuels, enabling building owners to cut operating costs and enhance occupant comfort while ensuring their facilities are sustainable and future-proof.

Upgrading or retrofitting new systems into old buildings is often a daunting thought for building owners. The assumption that major infrastructure changes, create disruption and costly operational downtime, is a fair one. However due to their modular nature and reduced need for extensive ductwork, Heat Recovery VRF systems can be more cost-effective to install, especially in retrofit projects. They are compact, making them suitable for buildings with limited space, especially in cramped inner-city areas.

Our experienced and highly skilled team at Watsons Building Services makes the retrofit or transition from older systems to advanced Heat Recovery VRF solutions as seamless and hassle-free as possible. Our team will assess your current system, identify areas for improvement, and design a customised retrofit or replacement plan that maximises efficiency and minimises downtime. We handle everything from installation to ongoing maintenance, ensuring optimal performance and reliability for years to come.

Case Study

Watsons Building Services undertook the task of designing and implementing the mechanical and electrical services for a 30,000ft² office building situated in Bradford City Centre. This refurbishment project, focusing on a structure dating back to the 1980s, spanned seven floors across two wings.

The outdated perimeter radiator heating system was replaced with highly efficient VRF comfort air conditioning systems, providing heating and cooling to each floor. Additionally, public health and ventilation services were meticulously integrated into numerous kitchenettes, shower rooms, and accessible toilets on each level.

Find out more about how our highly experienced HVAC specialists will work with you to discover the ideal VRF and Heat Recovery installation and maintenance solution for you today.