- 01535 652338

- mail@watsonsbs.com

MVHR: Improving Building Ventilation in a Post-Covid World

The massive impact of Covid-19 has been felt across every industry, with few if any able to predict how much change it led to. In the building industry, one of the biggest changes has been in ventilation solutions. Only a few short years ago this was not a huge priority in building plans, but with the rise of the first major pandemic in 100 years, it has pulled this service into sharp focus.

Covid has already accelerated the will to provide better ventilation solutions in both new builds and upgrades to pre-existing infrastructure. In many commercial premises such as hospitals and office blocks, the buildings are tightly sealed with few if any windows that can be opened. It could be argued that heating, ventilation, and air conditioning (HVAC) is the first line of defence against many viruses.

MVHR: The Complete Solution

Roof and foundation vents have been a long-standing method of building ventilation but lack the power required to ventilate a room quickly or reliably. Eventually, mechanical ventilation was invented to solve this problem, in the form of fans and extractor fans. However, they only work when manually activated and still do not properly ventilate large spaces.

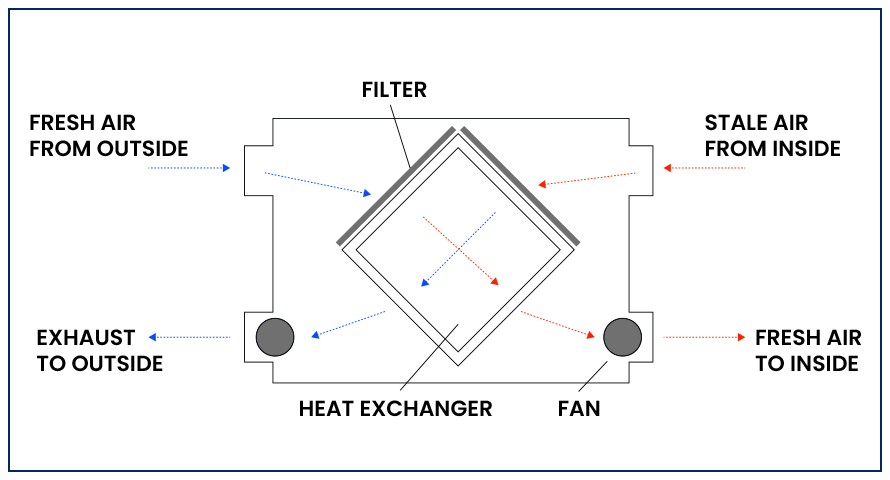

It was only when Mechanical Ventilation with Heat Recovery (MVHR) systems were introduced, that we saw a revolution in building air circulation and energy efficiency. MVHR is a system that efficiently manages air quality and energy consumption in buildings. It works by extracting stale air from the building while simultaneously bringing in fresh air from outside. This way, tightly sealed buildings can have a constant supply of fresh air at a desired temperature.

The Evolution of MVHR

It's hard to pinpoint exactly when MVHR systems were first invented or indeed introduced onto the market. Specific inventors and systems vary, but its roots can be traced back to innovative thinking of the 1970s and 80s, and major technological leaps of the 90s and 2000s.

The concept emerged from the need for more energy-efficient building design, brought on by the OPEC oil embargo of 1973-4. Builders in North America sought to design houses that were independent of oil as an energy source, mainly using the sun as a heat source. This led to the development of the heat recovery air exchanger and the hot water recovery system.

Based on the experiences of the North American builders, early MHRV systems critical to the design of energy-efficient buildings were developed, leading to their emergence as a viable alternative to the more conventional methods of the time. These early systems were less sophisticated than modern ones but several more significant technological leaps evolved MHRV further. The ability to effectively filter tiny particles was achieved in the late 80s, significantly enhancing air quality. In 1993, counter-flow heat exchangers became prevalent, further improved in the early 00s with the introduction of the plate exchanger. Then in 2010, the integration of smart controls enhanced system performance.

How Does MVHR Work?

An MVHR system feeds fresh air into a building without allowing heat to escape. In colder months, the heat from the stale air being extracted is transferred via a heat exchanger to the filtered fresh air coming in, so the air in the building is always fresh and warm, maintaining a high-quality fresh air supply with occupancy comfort in an energy-efficient way. The incoming air is distributed around the building via ducts that can be hidden in ceiling cavities.

In the summer months, extracted warm air from the building is sent outside while the cooler outside air is brought into the building through the filters. By bypassing the heat exchangers, the fresh air cools the building without the need for air conditioning. Humidity is also regulated, as the humid air inside is replaced with cool dry air, reducing the risk of mould growth and improving air quality.

What Are The Advantages Of MVHR?

Air Quality

Somewhat overlooked in the past, the COVID-19 pandemic has brought the quality of air to the top of most lists. These types of airborne viruses that can remain in the air for hours while being easily transmissible have made ventilation a priority, and the most effective method is MVHR. It also reduces the risk of people developing allergies, suffering from asthma and falling victim to respiratory diseases. Patients in hospitals stay healthier, students in schools concentrate better and staff in offices are less absent through viruses etc.

Energy Costs

Heating air requires a lot of energy and with fuel costs at a high, the price for heating a building is higher than ever. Furthermore, that energy is ultimately wasted as the heated air eventually escapes into the atmosphere and is lost. Not only is this a cost to the building owner, but it also negatively affects a building’s carbon footprint. MVHR retains up to 95% of the heat from outgoing air, greatly reducing the need to create new heat. The savings to both finances and the environment are huge.

Occupancy Comfort

Whatever the weather outside, MVHR maintains a consistent temperature to match seasonal needs. Systems now include sensors that integrate with Building Management Systems (BMS) for varying degrees of automation. Specialised sensors in kitchens, bathrooms and other wet rooms boost the airflow to combat humidity while others detect outside temperature and adjust the indoor environment accordingly.

Regulatory Compliance

In the UK, Building Regulations Parts F and L describe government requirements for building ventilation and the conservation of fuel respectively. MVHR can help buildings meet these regulations through highly effective ventilation and heat recovery. In 2025, a new set of government rules surrounding energy efficiency for new buildings will come into force. In keeping with the Net Zero 2050 target, the Future Homes Standard will require a reduction of 75% in a building’s carbon production, something that heat recovery will significantly contribute to.

How Watson Building Services Install MVHR

Whether it is a new building or a retrofit, careful planning is essential to get the best out of an MVHR system. From survey to design and installation, many factors must be considered, including ductwork placement, sealing and positioning of components. Without the right plan, even the best MVHR systems won’t function correctly. At Watson Building Services, our highly skilled experts will ensure that the MVHR system is installed to achieve peak efficiency so clients can enjoy the myriad benefits it brings.

The process for an installation varies according to the type and age of the property, but in general we follow these typical steps:

01 Site Survey

We provide a detailed examination of the site to establish suitability, component location, ductwork style and where the site needs sealing.

02 System Design

Based on the survey we put together the plan for the MVHR system including the correct ducting, positioning and BMS integration.

03 Installation

The MVHR unit, ducts, sensors and controls are installed in the designed positions. Monitoring and control are integrated into new or pre-existing BMS infrastructure.

04 Testing

The final phase before bringing the system online is to test it. We balance the system so that the extract flow rate is equal to the inflow rate and fully test all controls and sensors.

If there are positives to come out of the last few years, the focus on building air quality, and the new legislation surrounding that, is high on the list. The move towards a wider use of MVHR systems means better occupancy health in general, not just as a protection against the worst of a pandemic. The drop in energy consumption is also a significant step towards Net Zero, already complying with regulations yet to be actioned. For owners of buildings both new and established, MVHR makes a sound investment as an efficient, sustainable and future-proof HVAC system.

Tailored Ventilation for Your Needs

Our custom mechanical ventilation and heat recovery systems are engineered to meet your unique requirements. Experience better airflow and energy savings with solutions designed for you. Get in touch with our experienced engineering team for more information on solutions to suit your commercial or industrial building.